dry heat autoclave temperature|dry heat sterilization temperature chart : supermarket Dry heat process generally employs a temperature between 250°C and 400°C for varying time. The sterilizer is required to heat all parts of its load up to the specified temperature for a specified period long enough to achieve the desired sterility. . ENDOTOXIN CHALLENGE IN THE VALIDATION OF DRY-HEAT STERILIZERS The most controversial aspect . O papel grau cirúrgico oferecido pela Cisa é agente fundamental na manutenção da esterilização porque mantém uma verdadeira barreira isolante contra sujidades e micro-organismos. Possui um sistema que permite .

{plog:ftitle_list}

Autoclave sterilizes the materials by heating them up to a particular temperature for a specific period of time. The autoclave is also called a steam sterilizer that is commonly .

is autoclave dry heat sterilization

Sterilization is defined as killing or removal of all microorganisms, including bacterial spores. Sterilizing by dry heat is accomplished by conduction. The heat is absorbed by the outside surface of the item, then passes towards the center of the item, layer by layer. The entire item will eventually reach the temperature . See moreThere are two types of dry-heat sterilizers 1. the static-air type and 2. the forced-air type. The static-air typeis referred to as the oven-type sterilizer as heating coils in the bottom of the unit cause the hot air to rise inside the chamber via gravity convection. This type of dry-heat . See moreThe dry heat sterilization process is accomplished by conduction; that is where heat is absorbed by the exterior surface of an item and then passed inward to the next layer. Eventually, the entire item reaches the proper temperature needed to achieve sterilization. The proper time and temperature for dry heat sterilization is 160 °C (320 °F) for 2 hours or 170 °C (340 °F) for 1 hour, and in the case of High Velocity Hot Air sterilisers, 190°C (375°F) for 6 to 12 minutes.Dry heat process generally employs a temperature between 250°C and 400°C for varying time. The sterilizer is required to heat all parts of its load up to the specified temperature for a specified period long enough to achieve the desired sterility. . ENDOTOXIN CHALLENGE IN THE VALIDATION OF DRY-HEAT STERILIZERS The most controversial aspect .

Superheated steam is too dry for efficient heat transfer and is ineffective for steam sterilization. 2. What is the autoclave temperature range? Commonly recommended temperatures for steam sterilization are 250° F (121° C), 270°F (132°C) or 275°F (135° C). To kill any microorganisms present, the items being sterilized must be exposed to .Two commercial dry-heat sterilizers: (a) Cox fastest dry-heat sterilizer (6 min unwrapped at 375 °F (190 °C) temperature; 12 min wrapped) and (b) Wayne S1000 dry-heat sterilizer (standard 160–180 °C oven for instruments).

king brinell hardness tester price

Moist Heat vs. Dry Heat Aspect Moist Heat Sterilization Dry Heat Sterilization Method Uses steam under pressure or boiling water Uses hot air without moisture Temperature Range 121-134°C (for autoclaving) 160-180°C (for hot air ovens) Pressure Typically involves increased pressure (e.g., 15 psi in autoclaves) Atmospheric pressure Mechanism of . Studies for dry heat sterilizers typically have a wider temperature range than the corresponding moist heat sterilizers. This is due to the lower heat capacity delivered by dry heat vs. that delivered by steam. . Reducing both the exposure time and temperature. For dry heat studies, the heat penetration data generates an F H or F P-value. 24. . The method of heat circulation in dry-heat sterilizers is usually convection, which helps to ensure that the heat circulates throughout the sterilization chamber during the process. Mechanical convection is more effective; the sterilizer contains a fan or blower that continually circulates the heated air to maintain a uniform temperature . Autoclave sterilization is a method of sterilization that uses heat from pressurized steam to kill microorganisms. Autoclave sterilization is often used to sterilize medical and laboratory .

Exposure (Sterilization Phase): During this crucial phase, items within the autoclave are exposed to saturated steam at a specific temperature and pressure, typically around 121°C (250°F) at 15 psi for a duration contingent upon the load's composition and volume. This exposure is meticulously calibrated to ensure the inactivation of even the . This type of sterilization is also known as dry heat sterilization. This mechanism of heat treatment was introduced by French scientist Louis Pasteur in the late 1800s where he used dry heat for a brief period of time to kill off harmful microorganisms from the wine without altering its taste. Figure: Hot Air Oven. Image Source: Biology Reader.

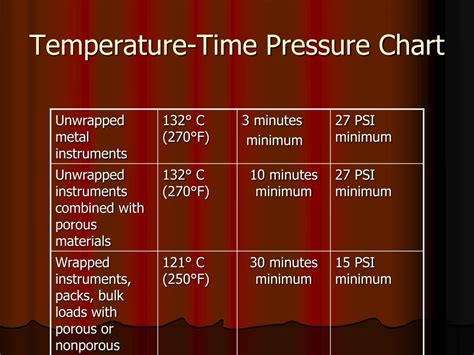

Autoclave Temperature and Pressure. Autoclave uses dry saturated steam under elevated pressure and temperature to ensure potent microbicidal activity. 121°C (250°F) and 132°C (270°F) are the ordinary temperatures maintained in a gravity displacement autoclave and pre-vacuum sterilizer at a standard pressure of 15 and 27 p.s.i, respectively.Dry heat sterilizers and sterilization equipment manufactured by Gruenberg. These dry heat sterilizers are the perfect fit for all sterilizing applications with superior results to steam. . The heat is absorbed by the item being sterilized and eventually it reaches the proper temperature needed to achieve sterilization. Operating temperatures . The temperature and exposure time are critical parameters. Usually, dry heat cycles will be performed at 160 to 190 °C with corresponding exposure times that range from 30 to 120 minutes. . For dry heat sterilizers, sensors must have an accuracy of ±0.5 °C, whilst an accuracy of ±1 °C is considered appropriate for depyrogenation ovens .Autoclave Temperature and Time Pressure Chart. STERILIZER: TEMPERATURE: PRESSURE: TIME: Steam autoclave: 121 C (250 F) 15psi: 15min: unwrapped items: 132 C (270 F) 30psi: . Dry heat (rapid flow) 190 C (375 F) 12min: packaged items: Chemical vapor: 132 C (270 F) 20-40 psi: 20min: Ethylene oxide: Ambient:

Beyond open flames, one common heat sterilization method is to use controlled dry heat in an enclosure—the dry heat sterilizer. Heating instruments to 325°F for two hours in a still air oven, or to 375°F for six to 12 minutes in a forced air oven, will kill all pathogens.

Dry heat sterilization uses hot air to raise the temperature of an item to above a validated temp. Utility navigation. Blog; Rental / Refurb ; Parts Store; 570.538.7200. Request a quote. Products . Dry heat sterilizers provide a number of advantages over other methods, including accuracy, ease of use, and cost effectiveness. .

Autoclave Machine, 1.5L Mini high Temperature Autoclave Box Dry Heat Cabinet with Timer for Nail Spa Pedicure Hairdressing Metal Tools . Brand: MAHOOMMAKH. 4.2 4.2 out of 5 stars 23 ratings. .99 with 7 percent .The knowledge of Dry heat sterilizer vs Autoclave is necessary for accurately selecting sterilization equipment, DHS uses hot air, while autoclave uses steam. October 23, 2024; . The sterilization temperature of a Dry Heat Sterilizer is higher than the autoclave and can go up to 230° C. The main reason is that DHS uses heaters to generate heat. B. atrophaeus spores (10 6) are used to monitor ETO and dry heat, and G. stearothermophilus spores (10 5) are used to monitor steam sterilization, hydrogen . Steam and low temperature sterilizers (e.g., hydrogen peroxide gas plasma, peracetic acid) should be monitored at least weekly with the appropriate commercial preparation of spores. If a .

dry heat sterilization time temperature

The dry heat sterilization process takes a long long time and is done at a high temperature (2 hours at 160°C). The total cycle time, including heating up and cooling down to 80°C can take about 10-11 hours, not the greatest solution for an active clinic that needs its instruments to be readily available.Autoclave Machine, 1.5L Mini high Temperature Autoclave Box Dry Heat Cabinet with Timer for Nail Spa Pedicure Hairdressing Metal Tools. 4.1 out of 5 stars. 22. .99 $ 42. 99. FREE delivery Sat, Sep 21 . Or fastest delivery Tomorrow, Sep 17 . Add to cart-Remove. More Buying Choices .42 (2 used & new offers)

Geisofu Autoclave Cleaner Machine 2L 110V/300W High Temperature Metal Cleaning Machine Box with Adjustable Temperature & Time Professional Dry Heat Cabinet Nail Tool Cleaner for Lab Home Salon. . it’s DRY HEAT AUTOCLAVE not steam for my fellow tattooers. Read more. 13 people found this helpful. Helpful. Report. Leila Tompkins. 5.0 out of .Compared with moist heat sterilization in an autoclave, sterilization by dry heat requires a higher temperature and longer process time due to the poor thermal conductivity of air. Therefore, materials such as nonaqueous products, metals, glass, powders, oils, and oil-based injectable pharmaceuticals and some polymers that do not lose their . Additionally, dry heat sterilization requires much more energy to effectively sterilize materials when compared to an autoclave. Many types of materials simply cannot endure heat sterilization . Dry Heat. Moist Heat. Radiation. Alcohols. Aldehydes. Oxidizing agents. Sterilization methods. Sterilization- physical and chemical methods. Dry Heat. Moist Heat. . Koch’s and Arnold’s steam sterilization is usually used for media which can easily decompose due to the high temperature in the autoclave.

Dry heat sterilizers rely on high temperatures and extended time to destroy microorganisms. Sterilization times range from 12-150 minutes, depending on temperature and manufacturer’s instructions. Common manufacturers of dry heat sterilizers include: Harvey; Dentronix; Cox; Sterident; SteriSURE; Wayne; Chemical/Vapor Dry-Heat Sterilizers. This method should be used only for materials that might be damaged by moist heat or that are impenetrable to moist heat (e.g., powders, petroleum products, sharp instruments). . ETO is more penetrating and operates at lower temperatures than do steam/formaldehyde sterilizers. Low-temperature steam formaldehyde .

Dry heat sterilizers, however, typically require a longer time, often 1-2 hours, due to their reliance on high temperature without pressure. This difference in time efficiency is a crucial consideration in settings where rapid sterilization is needed.

dry heat sterilization temperature chart

dry heat sterilization chart

Industrial Autoclaves are used in Manufacturing of composite, Glass, Cement, Vulcanizing, Food Processing, and Medical Waste Treatment. All South Gate Engineering tanks are built in strict conformance to A.S.M.E and/or customer .

dry heat autoclave temperature|dry heat sterilization temperature chart